Welcome to the blog of our jewelry page specializing in emeralds. Today, we invite you to discover the fascinating process behind the creation of our exquisite pieces, a meticulous work that combines tradition, technology, and a lot of passion. From the first sketch to the final delivery, each piece of jewelry is a unique work of art, and we want to share every stage of this wonderful journey with you.

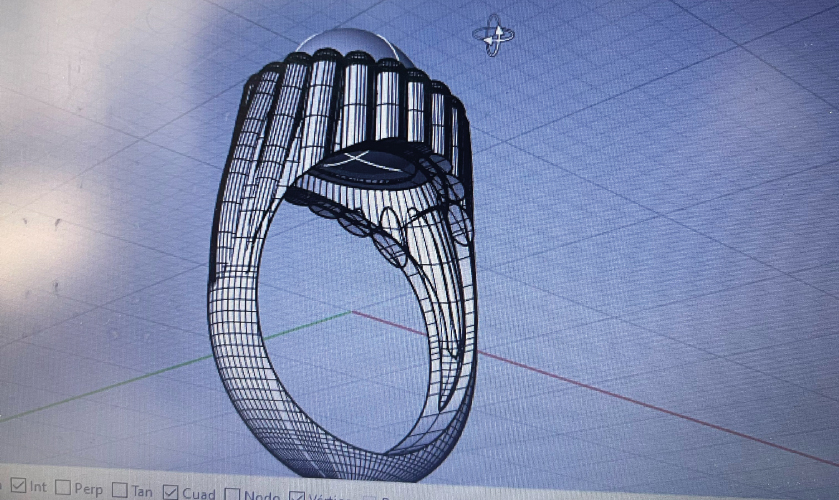

1. Creation Process: 2D and 3D Design

It all starts with an idea. Our expert designer, Daniela Cuero, transforms that idea into a 2D sketch, capturing every detail with precision and creativity. This initial drawing is fundamental as it defines the proportions, aesthetic details, and the arrangement of the emeralds.

Once the 2D design is approved, Daniela uses advanced software tools to transform the drawing into a three-dimensional model. This 3D design allows us to visualize how the jewelry will look from all angles and make necessary adjustments before proceeding to manufacturing. The 3D model is also essential for the next stage: wax printing.

2. Wax Printing and Metal Casting

With the 3D model finalized, we move on to wax printing. Using a 3D printer, we create an exact replica of the design in wax. This wax model is then used to make a plaster mold.

The plaster mold is heated so that the wax melts and leaves a perfect cavity in the shape of the jewelry. Molten precious metal (whether gold, silver, or platinum) is then poured into the mold. After the metal cools and solidifies, the plaster mold is broken, revealing the jewelry in its raw form.

3. Polishing and Creating Details for Setting

The freshly cast metal piece requires an intensive polishing process to remove any imperfections and prepare the surface for setting. Our craftsmen carefully polish the jewelry until a smooth, shiny finish is achieved.

Additionally, details such as engravings or special textures are added to enhance the beauty of the piece and further personalize it. Every line and curve is worked with precision to ensure a flawless result.

4. Stone Setting

Setting the stones is one of the most critical and delicate steps. Our jeweler selects the highest quality emeralds and places them in their respective positions in the jewelry. This process requires expert hands and extreme precision to ensure that each stone is firmly set and perfectly aligned.

5. Finishing Touches: Hallmarks and Rhodium Plating

Before the jewelry is completed, we add the finishing touches. This includes applying hallmarks, which certify the authenticity and quality of the metal. In some cases, a rhodium plating is applied to give the metal extra shine and protect it from oxidation and wear.

Since emeralds are delicate gemstones, we also apply specific treatments to protect them and ensure their durability. This can include applying natural oils that enhance their color and brilliance.

6. Delivery to Our Customer

Finally, the jewelry is ready to be delivered to its new owner. Each piece is presented in an elegant case, accompanied by a certificate of authenticity and a care manual to ensure that the jewelry remains in perfect condition for many years.

Delivering a piece of jewelry is a moment of great satisfaction for us, as we know we have created something unique and special that will accompany our customer in important moments of their life.

We hope you have enjoyed this journey through the process of creating our emerald jewelry. Every step is a testament to our dedication and passion for the art of jewelry making. Thank you for joining us on this journey!